Table of contents

Revamping your workshop is a strategic step toward boosting productivity and staying competitive in today’s manufacturing landscape. One pathway to modernization often overlooked is the integration of rebuilt CNC lathes, which offer a unique blend of cost efficiency and high performance. Discover in the following sections how choosing this equipment can transform your operations, providing both immediate and long-term benefits that make it worth your consideration.

Enhanced performance and reliability

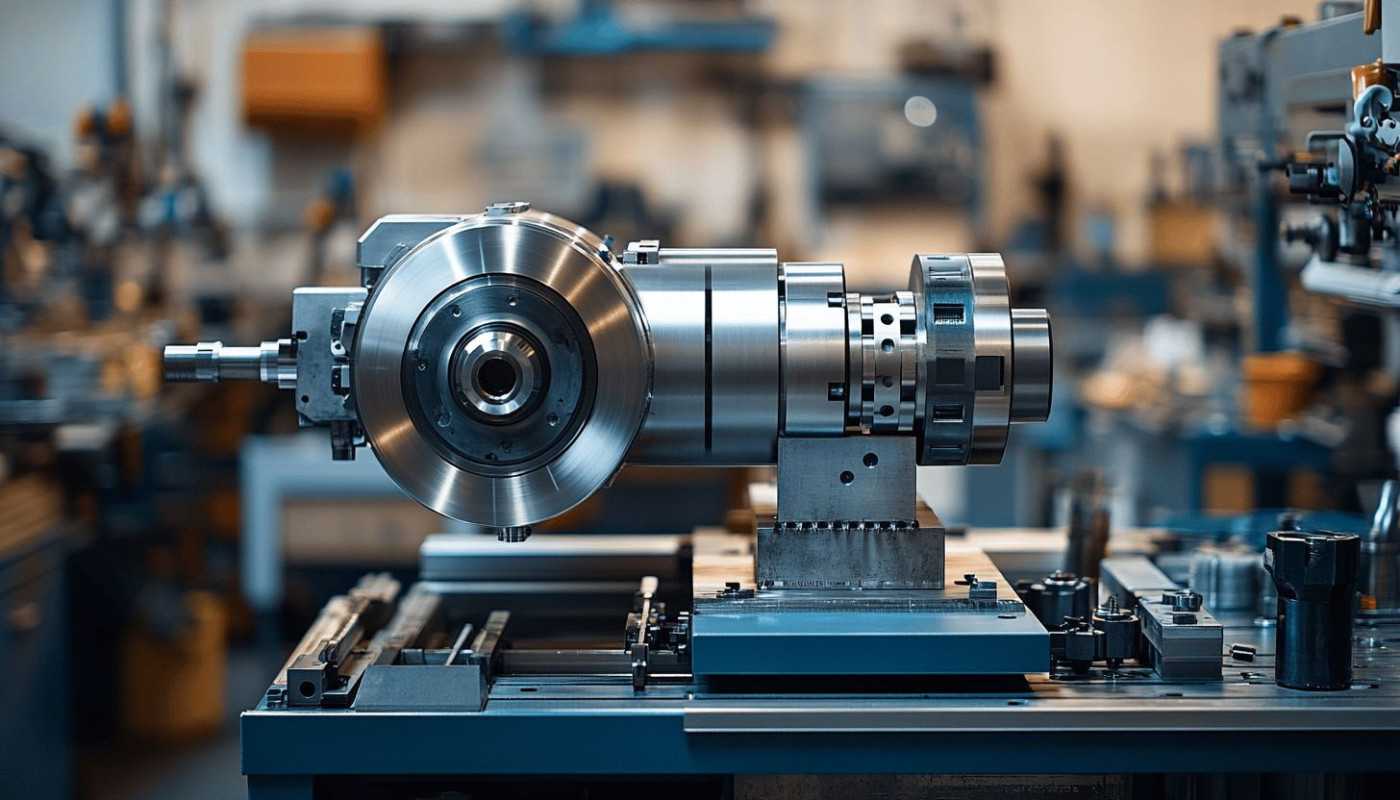

Rebuilt CNC lathes bring workshop efficiency to new heights by delivering performance and reliability that closely matches new equipment, yet at a fraction of the investment. Through advanced CNC retrofitting and comprehensive machine tool upgrades, older machines are transformed with state-of-the-art controls and enhanced mechanical components. Backlash compensation technology is implemented to minimize mechanical play in the drive systems, significantly increasing accuracy and repeatability. These upgrades allow for the retention of robust original castings, while improving spindle speeds, servo response, and digital connectivity, making them highly suitable for precision manufacturing applications. Workshop managers often find that rebuilt CNC lathes not only extend the service life of existing assets but also reduce downtime and maintenance costs, providing a cost-effective alternative to purchasing brand new machines.

Modern machine tool rebuilders integrate the latest advancements in CNC controls, such as touchscreen interfaces and improved programming capabilities, ensuring compatibility with current production demands. Precision machining is further improved through adaptive software algorithms, which optimize cutting paths and support complex geometries. Companies like SAMO Machine Tools exemplify this approach, offering comprehensive CNC retrofitting solutions that revitalize legacy equipment for demanding industrial environments. These enhancements empower manufacturers to achieve tight tolerances, high throughput, and consistent results, supporting sustainable production strategies while maximizing return on investment.

Cost-effective modernization

Opting for rebuilt CNC lathes offers substantial cost savings compared to investing in brand-new equipment, making them an attractive choice for workshop modernization. This approach minimizes capital investment by significantly lowering upfront expenditures, freeing up resources for other operational needs. Through CNC machinery rebuild, workshops can access affordable CNC solutions that integrate advanced features and up-to-date technology without the financial burden often associated with new machines. The total cost of ownership is also reduced, as rebuilt machines typically have lower depreciation rates and maintenance expenses, while still delivering reliable performance. As a result, businesses can enhance productivity, stay competitive, and upgrade their production capabilities—all while maintaining a responsible financial strategy.

Customization and flexibility

Rebuilt CNC lathes present significant opportunities for CNC customization, allowing workshops to adapt their equipment precisely to evolving production environments. By incorporating open architecture controls, these machines support flexible manufacturing, enabling integration with a wide range of automation upgrades and third-party hardware. This adaptability extends to bespoke tooling setups, custom workholding solutions, and tailored machinery programming that addresses unique component geometries or specialized processes. Digital integration is seamless, as modernized lathes can connect with smart factory systems, MES software, and real-time monitoring platforms, supporting Industry 4.0 initiatives and data-driven decision-making. In practice, such customization ensures that rebuilt CNC lathes remain responsive to new client demands, batch sizes, or changing material requirements, making them a strategic asset for manufacturers seeking agility without sacrificing performance or reliability.

Reduced downtime and maintenance

Rebuilt CNC lathes offer significant advantages for workshops aiming to minimize machine downtime and streamline CNC lathe maintenance. Enhanced with modern components and upgraded diagnostics, these machines enable predictive maintenance strategies that allow technical teams to anticipate and address issues before they become disruptive failures. This proactive approach not only leads to reduced downtime but also ensures greater machine reliability throughout daily production cycles. Predictive servicing relies on real-time monitoring and analysis, providing maintenance personnel with actionable insights to efficiently schedule interventions and avoid unexpected breakdowns. In addition, rebuilt lathes are often updated to support easier access to spare parts, further simplifying the maintenance process and reducing lead times when replacements are necessary. This combination of improved diagnostics, predictive maintenance options, and spare parts availability supports uninterrupted workshop operations and allows staff to focus on productivity rather than constant repairs.

Sustainable manufacturing practices

Choosing rebuilt CNC lathes is a strategic step toward sustainable manufacturing, as it significantly minimizes industrial waste and conserves raw materials. By refurbishing existing machinery, businesses avoid the environmental impact associated with scrapping old equipment and producing new units, supporting both eco-friendly machinery adoption and resource conservation. This approach aligns seamlessly with modern environmental compliance requirements, ensuring operations meet strict regulatory standards. Through a comprehensive life cycle assessment, organizations can assess the entire environmental footprint—factoring in energy use, emissions, and resource inputs—demonstrating that green CNC solutions contribute to reduced landfill contributions and lower carbon emissions. Investing in rebuilt CNC lathes not only extends machine usability but also exemplifies a commitment to sustainable manufacturing practices that benefit both the environment and long-term operational efficiency.

Similar

Exploring The Benefits Of Shared Office Spaces For Startups

Exploring The Impact Of Multimodal AI Models On Industry Efficiency

Is An Online Legal Platform Safe For Handling Legal Documents?

AI and Machine Learning: The Future of B2B Sales

Unlocking Growth: The Evolving B2B eCommerce Landscape

Transforming Customer Experience in the B2B Sphere

Mastering the Art of B2B Influencer Marketing

Crafting Irresistible Value Propositions for

Digital Transformation: A Game-Changer for B2B Marketing

Embracing Sustainability in B2B Supply Chains

Navigating the Intricacies of B2B E-commerce

How AI is Revolutionizing B2B Sales Strategies